1: It can deoxidize the product thoroughly, and reduce the defects. Through the deoxidization property of the refining agent, the oxygen in the liquid steel (including those in the deep layer) can be effectively and forcibly removed when the refining rod dips into the liquid steel. 1: It can deoxidize the product thoroughly, and reduce the defects. Through the deoxidization property of the refining agent, the oxygen in the liquid steel (including those in the deep layer) can be effectively and forcibly removed when the refining rod dips into the liquid steel.

2: It results the pure and clean liquid steel, and so the mechanical properties and the processing properties of the casting product will be enhanced. When the refining agent reacts with the liquid steel, it will make the liquid steel boiling, and make the impurities and gas floating upward easily. The refining agent has a proven scientifical composition of the different materials. And so the liquid steel environment resulting from its oxidation will create an enviornment in favor of the separation and collection of the impurities, then the impurities can be removed much more easily.

3: The price of the refining rod is reasonable low, and its use will be cost efficient. The rod has multiple functions and can solve a number of traditional problems at the same time. So it can save both the manufacturing time and cost of the product.

4: The refining rod is very easy to maintain and operate, which will be convenient for managing, and then resulting a much improved on-site environment. It can reduce the pollution, and create a much healther enviorment for the workers by significantly reducing or even eliminating of the harmful smoke, waste gas and strong light from the deoxidization processing

5: It has displayed distinct effects for the carbon steel and low alloy steel. It can greatly reduce the residual aluminum and alumina.

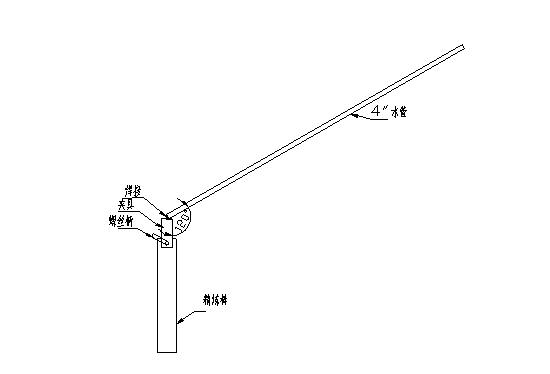

I: Welding fixture (see the figure below)

II: Place the refining rod close to the melting furnace, and bake for over 30 minutes below 100¡æ

III: Clamp tightly the refining rod. Place the flattened end of the refining rod close to the top of fixture groove, and tight it with screw. The screw handle shall face upward (to prevent burning-out).

IV: Before inserting the refining rod, remove the floating impurities on the surface of liquid steel, and wipe clean the surface of the refining rod.

V: Put the protection cover on.

VI: Maintain the normal insertion depth at 10 to 15 cm; According to the reaction extent, increase or reduce the insertion depth to the appropriate level.

VII: When the reaction is completed, let it stand still for 1 to 2 minutes, and then remove the slag and carry out the casting immediately.

VIII: For 100-130kg liquid steel, use the JL100; For 150-180kg liquid steel, use the JL150.

Notes:

I: Don¡¯t insert the rod too deep in the liquid steel, otherwise the liquid steel may spill out, and it is dangerous!

II: Do not use the wetted refining rod. The refining rod must be stored in a dry condition, and kept away from damp.

|